Wuhan HGGuanghe Technology Co., Ltd.

Metal Laser Engraving - Application Guide

Overview of characteristics of metal materials

Metal is one of the most widely used materials in the industrial field, which can be processed in various forms, such as cutting, carving, welding, smelting, and processing into various industrial products.

Laser processing metal

Laser technology possesses the characteristics of high precision and high energy, allowing for effective interaction with metal materials. Currently, it is one of the most widely recognized processing technologies in the industry. Whether engraving patterns on surfaces or cutting into specialized shapes, it meets various needs.

What can you get here?

In this guide, we offer expertise and advice to teach you how to machine metal properly. Whether you are engraving on metal for the first time or looking to buy related equipment for laser processing, you will find relevant advice in this guide. We will introduce you to several forms of laser processing for metals, the types of lasers most suitable for each form, and other associated applications. Once you know how to make the most of lasers in metalworking, a new world will open for you

Equipment recommendation

Buy directly or want to experience the sample?

Click here ,Shop now

What types of metal materials are suitable for laser processing?

Stainless steel

Laserable Aluminum

Hardened metals

Alloyed steels

High-speed steels

Laserable Titanium

Laserable Carbides

Laserable Brass

Laserable Copper

Precious metals (gold, silver, platinum)

Coated metals

Application of Laser in Metal Materials

1.Engraving

Laser engraving is currently the most widely used process, you see all walks of life, basically have its figure, such as the information on the metal nameplate, pet card, lighter, jewelry engraving, ornament engraving.

Laser Ablation: This process involves vaporizing and removing the top coating of the material, exposing the underlying metal.

Laser Annealing: This laser metal engraving processes a high-temperature exposure that alters the metal, softening and recrystallizing the material to leave a high-contrast mark.

Laser Polishing: This technique achieves a reflective finish on metal by heating it until it changes color.

2.Welding

Laser welding of different materials can not only meet the requirements for shape but also ensure strength, as seen in applications such as metal cans, billboards, containers, and transport vehicles and so on.

Heat conduction welding: Laser radiation heats the surface to be processed, and the heat diffuses inward through conduction, allowing the materials to melt and bond together under external pressure.

Deep penetration welding: When the laser power density reaches a certain threshold (generally greater than 106 W/cm²), the material's surface rapidly melts and vaporizes under the laser beam's irradiation, forming a small hole.

Laser brazing: A filler material (filler metal) with a lower melting point than the base metal is used. The laser beam focuses on the filler metal, causing it to melt and flow into the gap of the base metal to create a joint.

Laser hybrid welding: This method combines laser welding with other welding techniques, such as laser-arc hybrid welding and laser-plasma arc hybrid welding.

3.Cut

Laser cutting can achieve very high accuracy, with errors typically controlled within a few threads or even smaller. For parts with complex shapes, it can accurately cut according to design requirements, ensuring consistency and precision in size. This gives laser cutting irreplaceable advantages in precision machinery manufacturing, electronic components manufacturing, and other fields. The process can be divided into vaporization cutting, melting cutting, oxidation melting cutting, controlled fracture cutting, and more.

4.Cleaning

Laser cleaning is very environmentally friendly. Come and give it a try. Pulse Cleaning: The high energy of the pulsed laser beam is used to instantaneously act on the surface of the object being cleaned. The pulsed laser releases energy in a very short time (usually at the nanosecond or picosecond level), causing pollutants to rapidly heat up, expand, vaporize, or decompose after absorbing the laser energy, thus separating from the object's surface.

Continuous Cleaning: This method involves continuously irradiating the surface of the object with a laser beam outputs continuously. Under the influence of the continuous laser, pollutants gradually absorb laser energy, heat up, undergo physical or chemical changes, and are ultimately removed from the surface of the object.

Lasers most suitable for metal processing

1.Fiber Lasers The primary advantage of using this machine is its superior power. Engraving on metal doesn’t require pre-treatment, as the fiber laser wavelength penetrates bare metals and hard plastics more effectively. However, the only disadvantage of the fiber laser for metal engraving is that it is limited to metals and hard plastics. Applications involving materials such as wood, glass, leather, and acrylic are often too transparent for the fiber laser's wavelength; it may pass through these materials and strike the engraving table below.

2.CAN YOU USE A CO2 LASER FOR METAL ENGRAVING?

CO2 laser engravers are commonly used for applications such as wood, glass, leather, and acrylic. However, if you apply a special laser bonding agent, you can also mark metals with a CO2 laser engraver. This marking agent is used to treat the metal's surface before engraving, similar to how paint primer is applied to metal surfaces.

With simple laser bond spray, you can turn your CO2 laser into a stainless steel laser engraving machine! Coated metals like painted brass and anodized aluminum do not require this treatment. One advantage of CO2 lasers for metal engraving is that they leave marks on the surface, preserving the integrity of the product. CO2 laser engravers are more affordable, while fiber lasers are recognized for their durability and low maintenance. An additional disadvantage of using a CO2 laser for metal engraving is the need to coat the metal beforehand. It is also less efficient, as the laser must operate at low speed and high- power settings to effectively use the laser marking agent.

Our advantage

Professional customer service

Comprehensive training and installation

Competitive pricing

Quality assurance

Product improvement

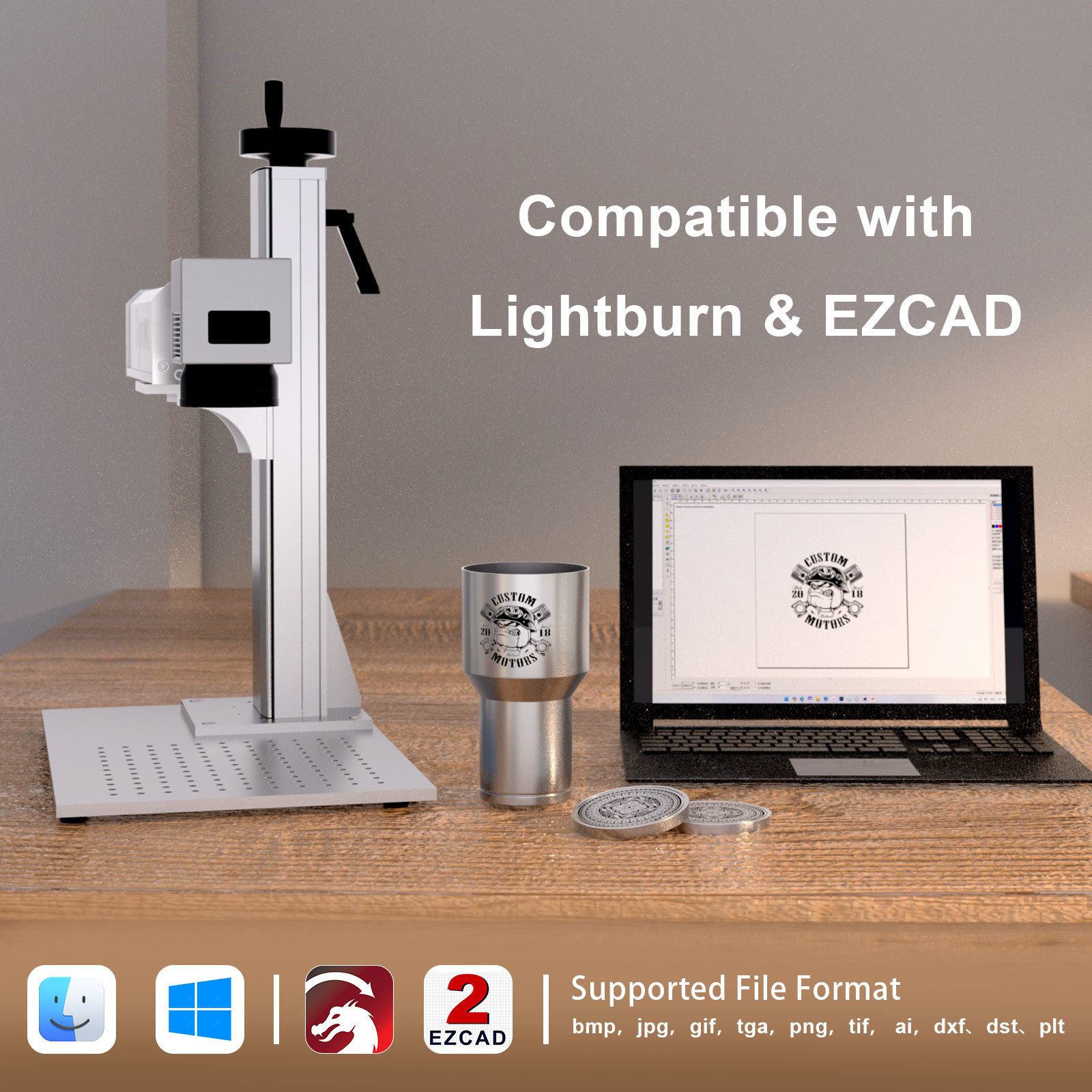

Recommended equipment for metalworking

LG、G-BOX、Smart Metal engraving: LG, G-BOX, Smart

EW Metal welding: EW

Clean Metal cleaning:Clean

Related Products

Crafted by You

Be In Touch With Us.

FOLLOW US