Wuhan HGGuanghe Technology Co., Ltd.

The Application of Laser Technology in Medical Device Manufacturing

Release time:2024-10-29

With the continuous advancement of technology, the medical device industry is entering a golden age. Currently, laser processing technology is widely used in manufacturing medical devices, including laser marking, welding, cutting, and more. How does laser technology transform into the "sharpest scalpel," empowering the innovative development of the medical device industry?

In response to the ever-growing production demands of this industry, HGLaser is keenly attuned to its pain points across various fields and application scenarios. Leveraging the significant advantages of high precision, flexibility, cleanliness, and strong adaptability in laser processing, we are committed to providing comprehensive "Laser + Intelligent Manufacturing" solutions to our clients, ranging from intelligent equipment to automated production lines and smart factories. Let’s delve into the tailored solutions HGLaser has provided specifically for medical device manufacturing!

Laser Marking

In the field of medical devices, laser marking is commonly used to ensure safety and traceability by marking product surfaces and outer packaging, such as UDI codes. Additionally, it is employed for biopsy needles.

Corrosion-Resistant Marking for Medical Surgical Instruments

Applications:

Using laser technology to mark UDI codes, characters, logos, and other identifiers on materials such as stainless steel, titanium, titanium alloys, nitinol, anodized titanium, and cobalt-based alloys.

Advantages:

- Leaves no bacteria residue at the marking site.

- Provides permanent identification, resistant to repeated sterilization.

-Allows for visual recognition positioning marking, compatible with multiple products, achieving intelligent marking of unordered incoming materials.

Applications:

Laser marking for medical implants achieves permanent identification.

It is used for marking serial numbers (SN), UDI codes, and two-dimensional codes for interactive chronic disease management systems on blood glucose meters, enabling automated production.

Laser Welding

The difficulty of welding medical devices arises from the differences in melting points, expansion coefficients, thermal conductivity, and specific heat capacities of dissimilar materials. Additionally, the products often have fine dimensions and require high precision. Only precision laser welding can meet these processing requirements.

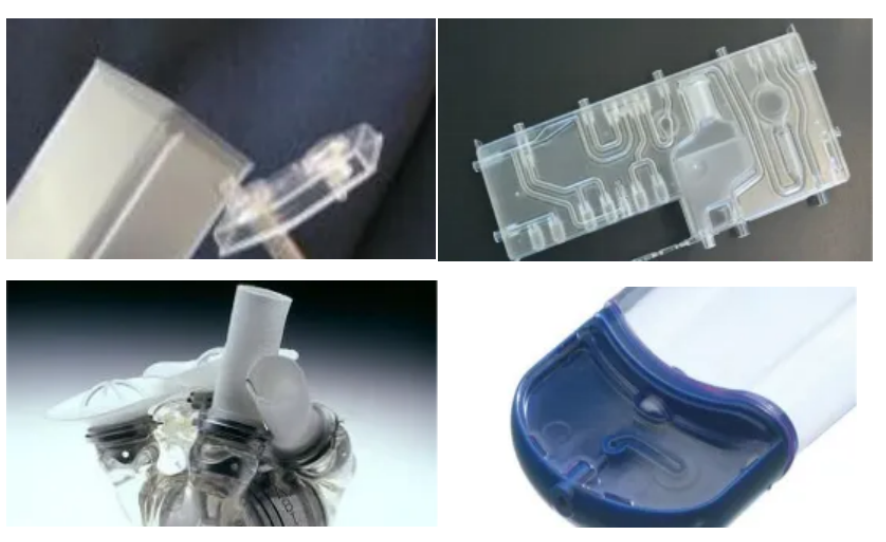

Medical Consumables Plastic Welding

Application:

Targeting the medical polymer materials industry to achieve welding of dissimilar plastic materials.

Advantages:

- High-speed digital scanning head with fast response

- Controllable high precision, good sealing, and strong compatibility

- Customized fixtures and light sources based on product materials

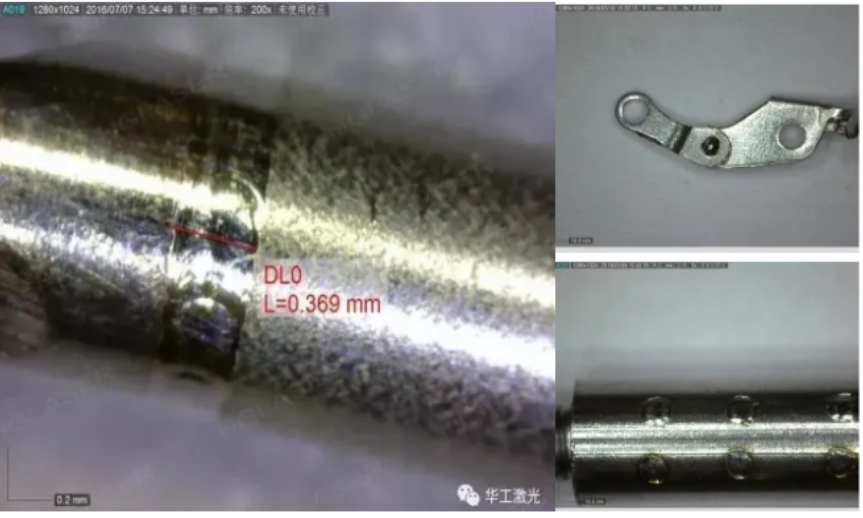

Medical Minimally Invasive Intervention Equipment Welding

Previous Page

Related News

Be In Touch With Us.

FOLLOW US